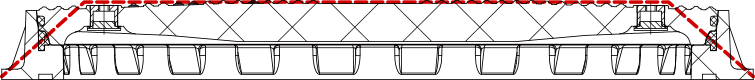

By improving the mechanical properties of the material and optimizing the structural design, the manhole cover and the well seat have a high degree of fit, a stable structure, and small deformation. The product will not produce deformation, displacement, or cracking during installation and use.

BETTER COVER's independently developed SMC composite material has high density, low water absorption (0.15mg) and good waterproof properties.

At the same time, the design of the sealing ring and structure achieves good sealing performance.

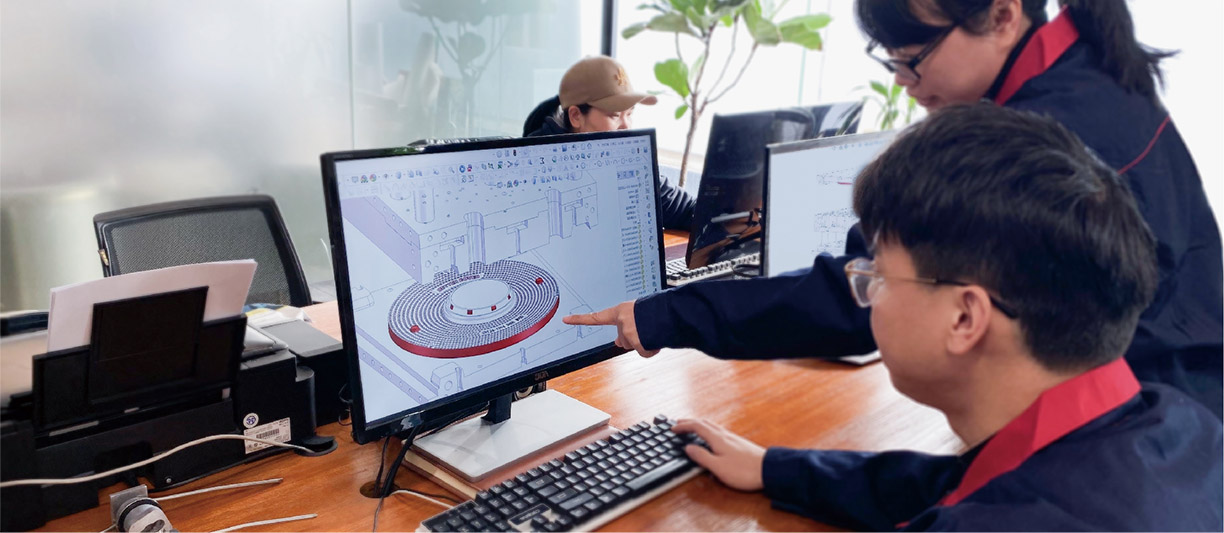

BETTER COVER's R&D team can carry out customized development of products of different sizes,

from product structure design, to mold design and manufacturing, to mass production of finished products.

Our core engineers have 20 years of experience in the industry.

Enhance compression resistance→ thereby achieving product lightweight

High output and low cost

High output and low costComposite materials are more abundant than cast iron and other metal resources, with higher cost performance. One-time molding, faster production process and lower manufacturing cost than cast iron products.

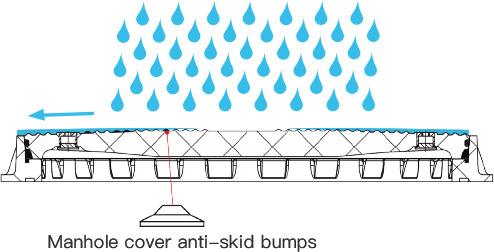

Strong waterproof

Strong waterproofThe manhole cover and well seat are made of the same SMC composite material and are formed by mold pressing, which has high dimensional accuracy and ensures the stability of the sealing gap between the well cover and the well seat. Moreover, a rubber seal with oil and gas resistance, wear resistance and high and low temperature resistance is used between the well cover and the well seat, which makes the complete set of well covers have good anti-leakage performance.