2022-09-04

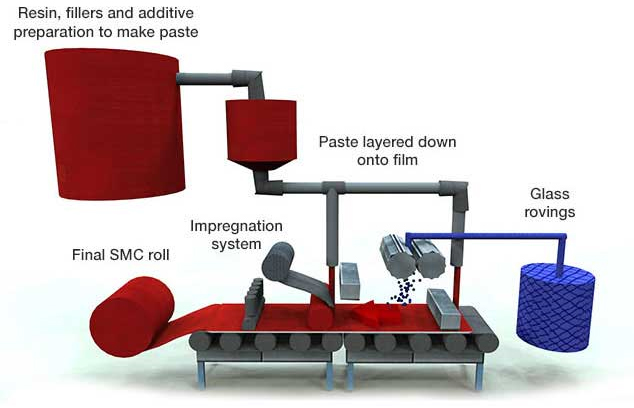

Manufacturing process including pulping, premix, placing glass fibers, steeping and rolling etc.

| Antistatic Standard rules the resistance on the material surface is 106-8 Ω. We actually adopted SMC material which surface resistance is 104-6 Ω to make the product has better antistatic performance. | Chemical Resistance SMC material has good chemical resistance (acid, alkali, salt, organic solvent, etc.), Long-term use in the environment of underground or oil gas will not result in the change of material structure or performance. | Waterproof SMC material has high density and low water absorption (0.15mg). It has excellent waterproof. |

| Resistance to deformation capacity and bearing capacity By improving the mechanical properties of materials and optimizing the structural design, make the product in the process of installation and use not cause deformation, displacement and cracking phenomenon. | High and low temperature resistance Thermal deformation temperature of SMC materials is greater than 200 ℃. It can be in -55℃~+150℃ for long-term use and the environment temperature changes will not affect product performance. | Low thermal expansion coefficient SMC Material has very low thermal expansion coefficient (12 × 10-6 / ℃), same as steel material, to ensure that products in the process of temperature changes will not cause the looseness of the filled soil around. |