With the development of composite material manhole covers in recent years, because of its various advantages, composite manhole covers are gradually replacing the most commonly used ductile iron manhole covers in gas stations, and become the best manhole cover choice for new gas stations or gas station renovations.

In order to save the area occupied by gas stations, and buried oil tanks are relatively safer and more reliable, more and more gas stations install oil tanks under the gas stations and driveways. Therefore, gas station manhole covers have higher and higher requirements for load-bearing and sealing performance.

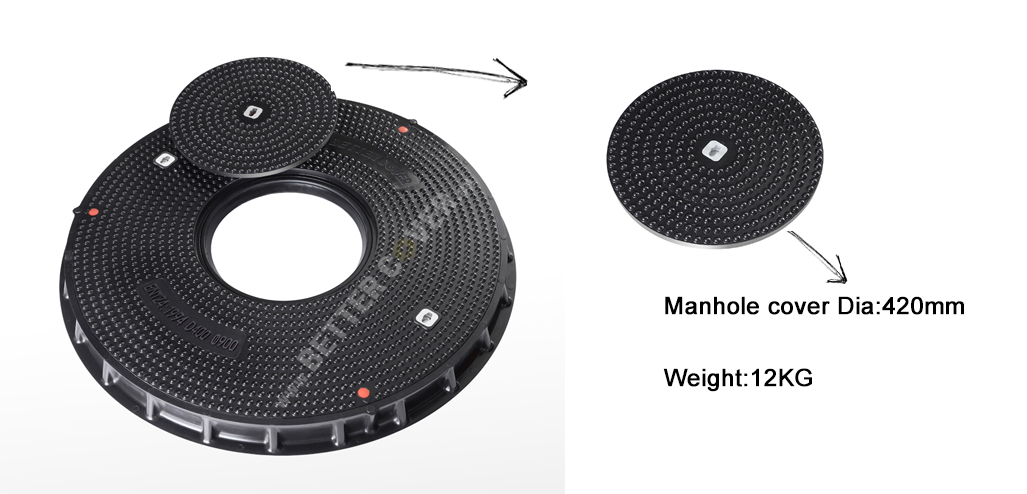

Gas stations often have large and heavy trucks driving. The manhole covers installed at the gas stations need to use heavy-duty D400 manhole covers to meet the daily use requirements of the gas station. It is best to use embedded manhole covers with locking structures to prevent vehicles from frequently pressing over the manhole covers. Causing the manhole cover to loosen, displace or fall off.

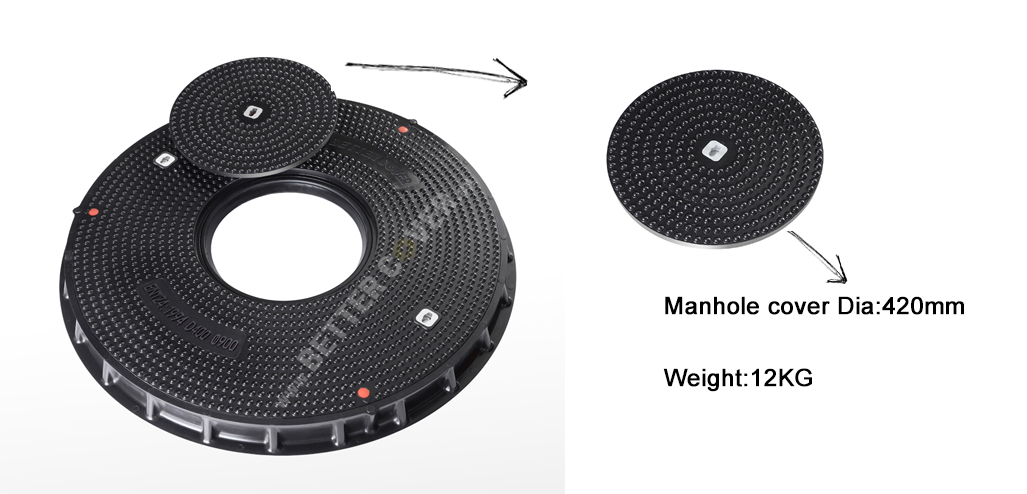

Locking gas station composite manhole cover with inspection hole, the inspection manhole cover is lighter and can be easily opened by a single person, which is convenient for the gas station staff to inspect, maintain and clean the oil tanks daily, and improves the work efficiency of the gas station.

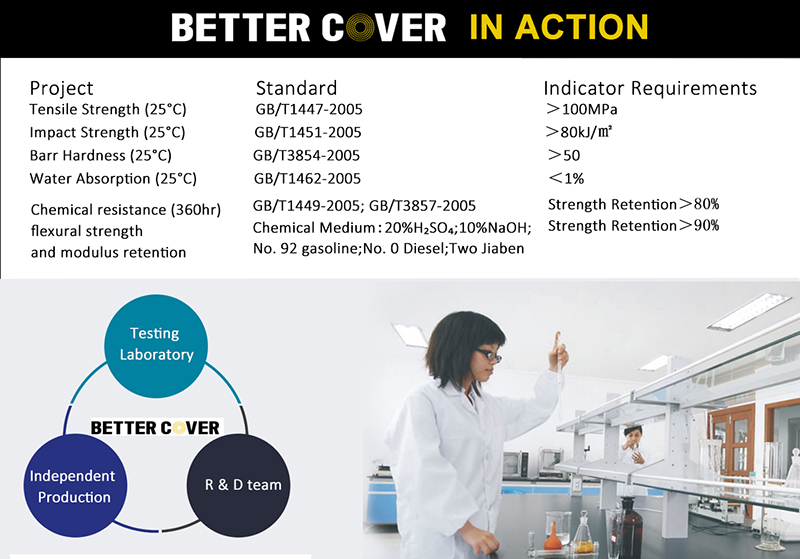

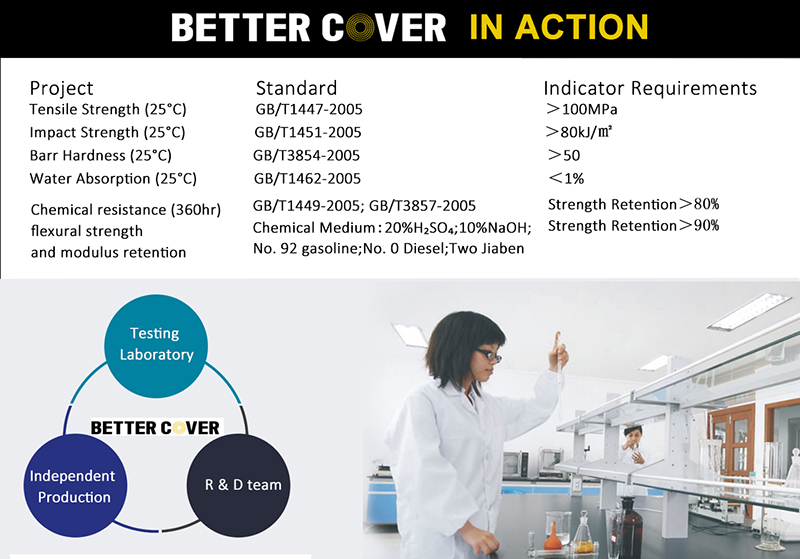

Gas stations have special environmental requirements for chemicals and petroleum products, requiring manhole covers to have higher corrosion resistance. Composite manhole covers are usually made of corrosion-resistant glass fiber reinforced plastic (FRP), which has better corrosion resistance and can better resist chemicals. corrosion and reduce the risk of accidents.